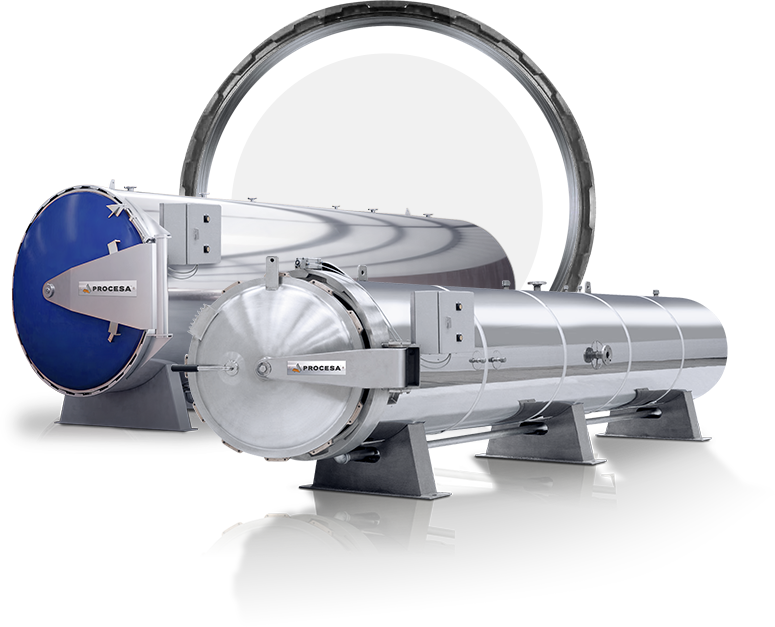

Our autoclaves, manufactured and stamped under ASME code standards, guarantee efficiency and safety. They can be automated according to our clients' requirements for product loading and unloading, as well as for strict temperature and pressure control, achieving perfect cooking and energy savings.

They are manufactured with manual or hydraulic opening, and the movement of the lids can be lateral, orbital, or upward. They are designed with a mechanized loading and unloading system, which significantly reduces the time in this phase of the process.

They are constructed in various capacities ranging from 500 to 20,000 liters. Using stainless steel SA-240-T-304 or SA-240-T-316 as per the requirements of each of our clients, and with an innovative heating system, this represents a significant savings in steam consumption and high heating efficiency.

Our stills are manufactured using 99.99% pure copper. They are essential in the tequila and mezcal industry to enhance the quality and flavor of distilled beverages. Copper serves as a catalyst in chemical reactions during distillation, eliminating unwanted compounds and promoting the formation of characteristic flavors and aromas. These systems ensure precise distillation and the production of high-quality tequila and mezcal, with distinctive flavor profiles widely recognized in the industry.

Nuestros alambiques son fabricados utilizando cobre de 99.99% de pureza. Son esenciales en la industria del tequila y el mezcal para mejorar la calidad y el sabor de las bebidas destiladas. El cobre cumple la función de catalizador en las reacciones químicas durante la destilación, eliminando compuestos no deseados y favoreciendo la formación de sabores y aromas característicos. Estos sistemas garantizan una destilación precisa y la obtención de tequila y mezcal de alta calidad, con perfiles de sabor distintivos ampliamente reconocidos en la industria.

Our brick ovens provide a controlled heat environment, allowing for the caramelization of sugars and the development of exceptional flavors. The tahonas, crafted with granite stone, crush agave piñas to extract the essential juices.

These traditional methods guarantee the authenticity and quality of the final products in the tequila and mezcal industry.

Fermentation vessels are crucial elements in the tequila and mezcal industry, as they enable the fermentation of agave musts, transforming them into alcohol. These containers provide precise control over the process, allowing yeast to work on sugars to produce ethanol.

This process ensures the development of characteristic flavors and aromas while guaranteeing the quality and uniformity of the final products in the tequila and mezcal industry.

Los fermentadores son elementos cruciales en la industria del tequila y el mezcal, ya que permiten la fermentación de los mostos de agave, transformándolos en alcohol. Estos receptáculos brindan un control preciso del proceso, lo que permite a las levaduras trabajar en los azúcares para producir etanol.

Este proceso garantiza la obtención de sabores y aromas característicos, además de asegurar la calidad y la uniformidad de los productos finales en la industria del tequila y el mezcal.