Our microbrewery is a small-scale brewery that produces less than 6 million barrels of beer per year.

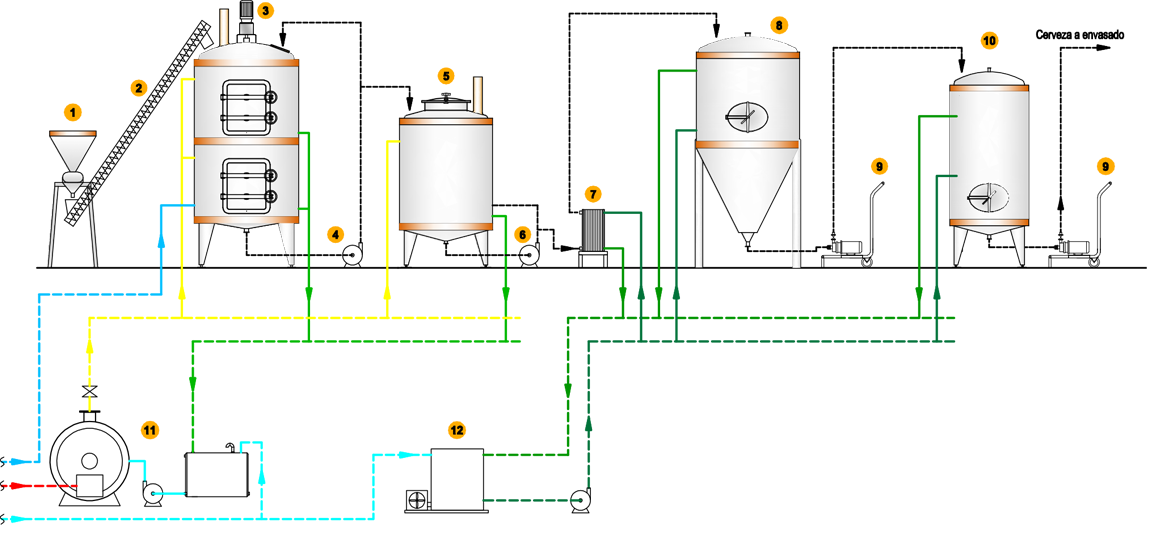

The process begins with the malt mill, followed by transportation to the mash tun, where it is mixed with hot water to convert starches into fermentable sugars. Then, the kettle comes into play, cooking the wort with hops to add flavor and aroma. Next, the heat exchanger quickly cools the wort, preparing it for fermentation in the fermenter, where yeast converts sugars into alcohol. The final beer is stored in the maturation tank to develop its flavor and unique characteristics.

We offer a complete line of custom equipment, such as pumps, heat exchangers, and boilers, meeting rigorous quality standards. Additionally, we provide customization services, specialized technical support, and efficiency in beer production.

FLOW DIAGRAM