Our fermenters represent an essential component in the winemaking industry, playing a fundamental role in the alcoholic fermentation of grapes, transforming them into wine. These vessels exert precise control over factors such as temperature, oxygenation, and fermentation time, allowing the conversion of sugars into alcohol.

Thanks to their contribution to the stability of the fermentation process, fermenters play a crucial role in ensuring the quality and consistency of the wines produced in the winemaking industry.

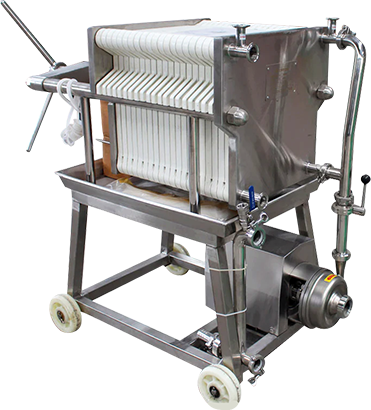

Our filtration systems are essential components in the winemaking industry, responsible for removing unwanted particles and sediments from wine. These devices contribute to the clarification and stabilization of wine, resulting in an improvement in its appearance and quality. When used appropriately, they guarantee the removal of impurities and the production of clean and brilliant wines.

Nuestros sistemas de filtración son componentes esenciales en la industria vitivinícola, encargados de eliminar partículas y sedimentos no deseados del vino. Estos dispositivos contribuyen a la clarificación y estabilización del vino, lo que se traduce en una mejora en su apariencia y calidad. Cuando se emplean de manera adecuada, garantizan la eliminación de impurezas y la obtención de vinos limpios y brillantes.

Rigorously constructed with certified stainless steel and carbon steel materials to ensure their tightness and safety. They are manufactured in compliance with applicable codes based on the products to be stored.

These tanks are designed in various capacities and shapes to meet industry demands. Additionally, they offer the possibility of incorporating a range of additional features, such as mixers, heating, and cooling systems.

We manufacture Cleaning in Place (CIP) systems that are essential in the winemaking industry to ensure efficient cleaning and hygiene of equipment and pipelines used in wine production. These systems automate the cleaning process, ensuring the quality and purity of the wine while saving time and resources. They reduce the risk of cross-contamination, maintain consistency in wine quality, and comply with food safety standards.

Fabricamos sistemas CIP (Cleaning in Place) que son esenciales en la industria vitivinícola para garantizar la limpieza eficiente y la higiene de los equipos y tuberías utilizados en la producción de vino. Estos sistemas automatizan el proceso de limpieza, asegurando la calidad y pureza del vino, al tiempo que ahorran tiempo y recursos. Reducen el riesgo de contaminación cruzada, mantienen la consistencia en la calidad del vino y cumplen con los estándares de seguridad alimentaria.

At Procesa, we manufacture semi-automatic duplex barrel washers that play an essential role in the winemaking industry. These equipment ensure effective cleaning of wine barrels, removing residues and microorganisms to preserve the quality and flavor of the wine. Our barrel washers are efficient, time-saving, ensure consistent cleaning, and comply with food safety standards.

These equipment enable the efficient crushing of olives, extracting the precious olive oil. Our crusher mills are effective, save time and resources, and guarantee the quality of the oil.

Moreover, they comply with quality and food safety standards.

Estos equipos permiten la trituración eficiente de las aceitunas, extrayendo el preciado aceite de oliva. Nuestros molinos trituradores son eficaces, ahorran tiempo y recursos, y garantizan la calidad del aceite.

Además, cumplen con los estándares de calidad y seguridad alimentaria.

At Procesa, we manufacture olive paste mixers designed for precise and homogeneous mixing of the paste, a critical step in producing high-quality olive oil. These equipment allow the uniform incorporation of essential components of the paste, contributing to efficient oil extraction with all its natural characteristics intact. Our mixers stand out for their efficiency, time and resource savings, and for maintaining the highest standards of quality and food safety.

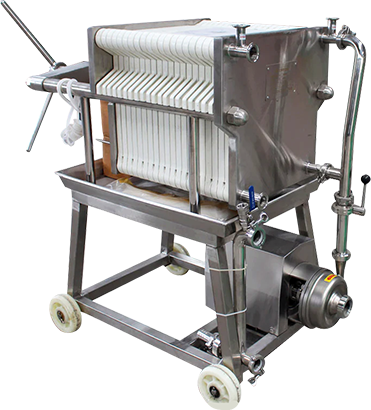

These equipment play a fundamental role in the clarification and purification of oil, ensuring its purity and quality. The plate filters we produce are highly efficient, resulting in time and resource savings for our customers.

Estos equipos tienen un papel fundamental en la clarificación y purificación del aceite, asegurando su pureza y calidad. Los filtros de placas que producimos son altamente eficientes, lo que significa ahorro de tiempo y recursos para nuestros clientes.